-

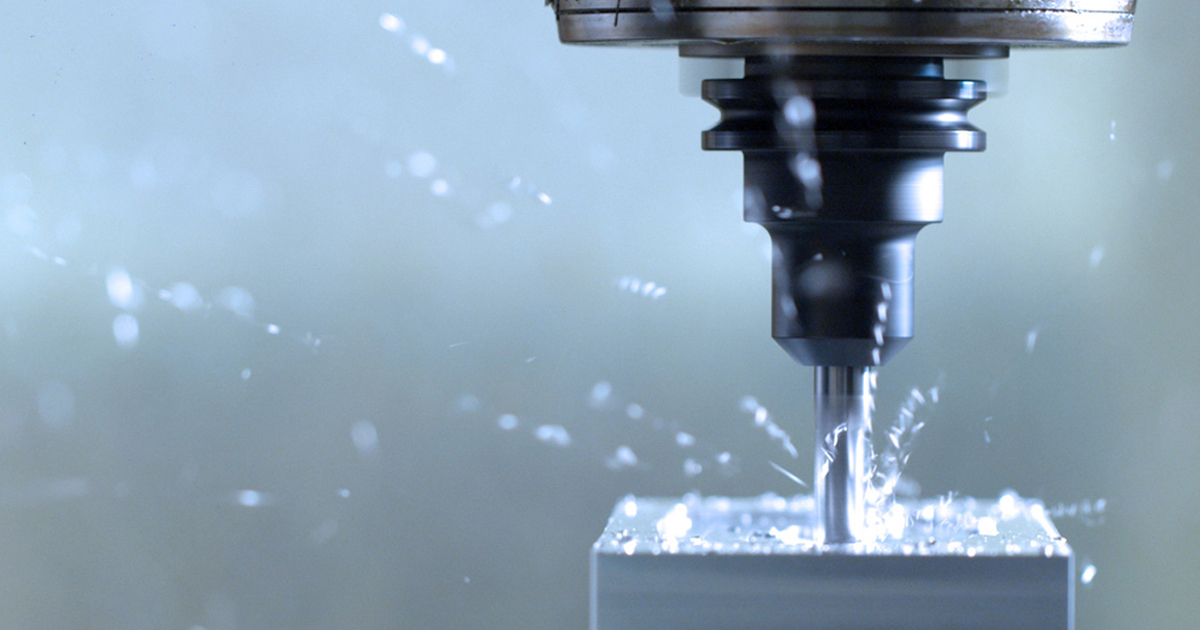

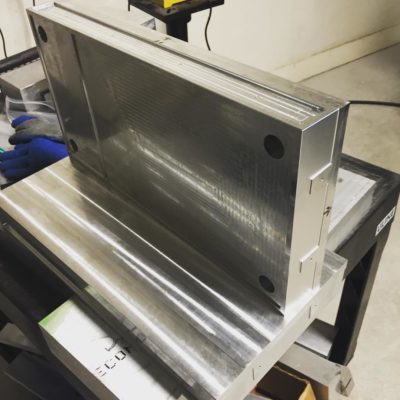

Inside Our First Pay It Forward Prototype Machining Project: The Making of a Guitar Mold

You can’t take your product idea to market without it. Investors need to see it before they’ll financially back you. But not every small business owner or

-

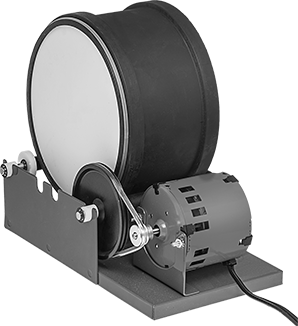

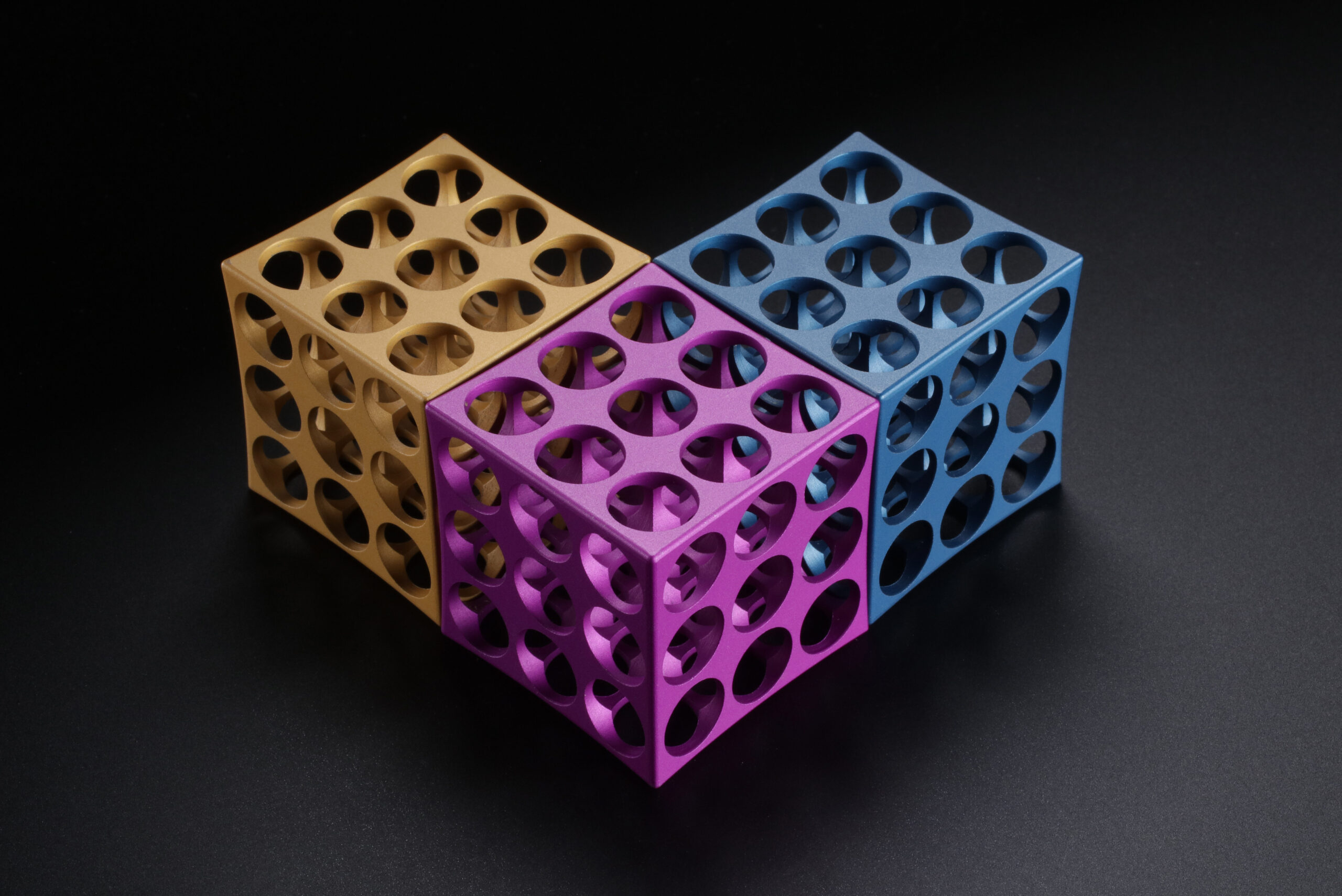

Is Tumbling the Right Finishing Process for Your Part?

At KAD, we’re proud to offer a wide range of finishing services, including sandblasting (also known as media blasting), small-part powder coating, hardware installation, and

-

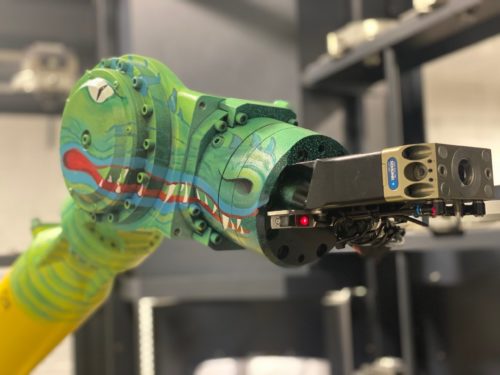

The Power of Teamwork in Manufacturing

Hello, reader—Brian Kippen here, owner and founder of KAD, back with another installment of our new series, The Future of Manufacturing. This series spotlights problems

-

Let’s Bring Manufacturing Education into the 21st Century

Hello, reader—Brian Kippen here, owner and founder of KAD. Welcome to another installment of our new series, The Future of Manufacturing, wherein I share the

-

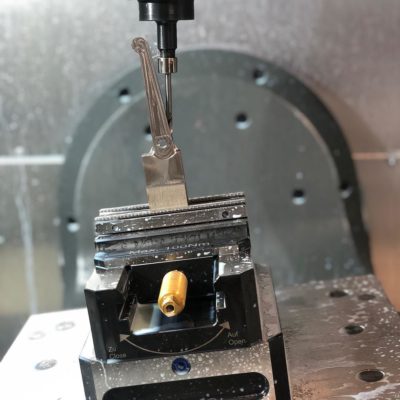

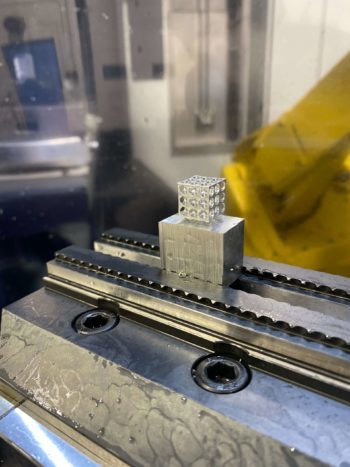

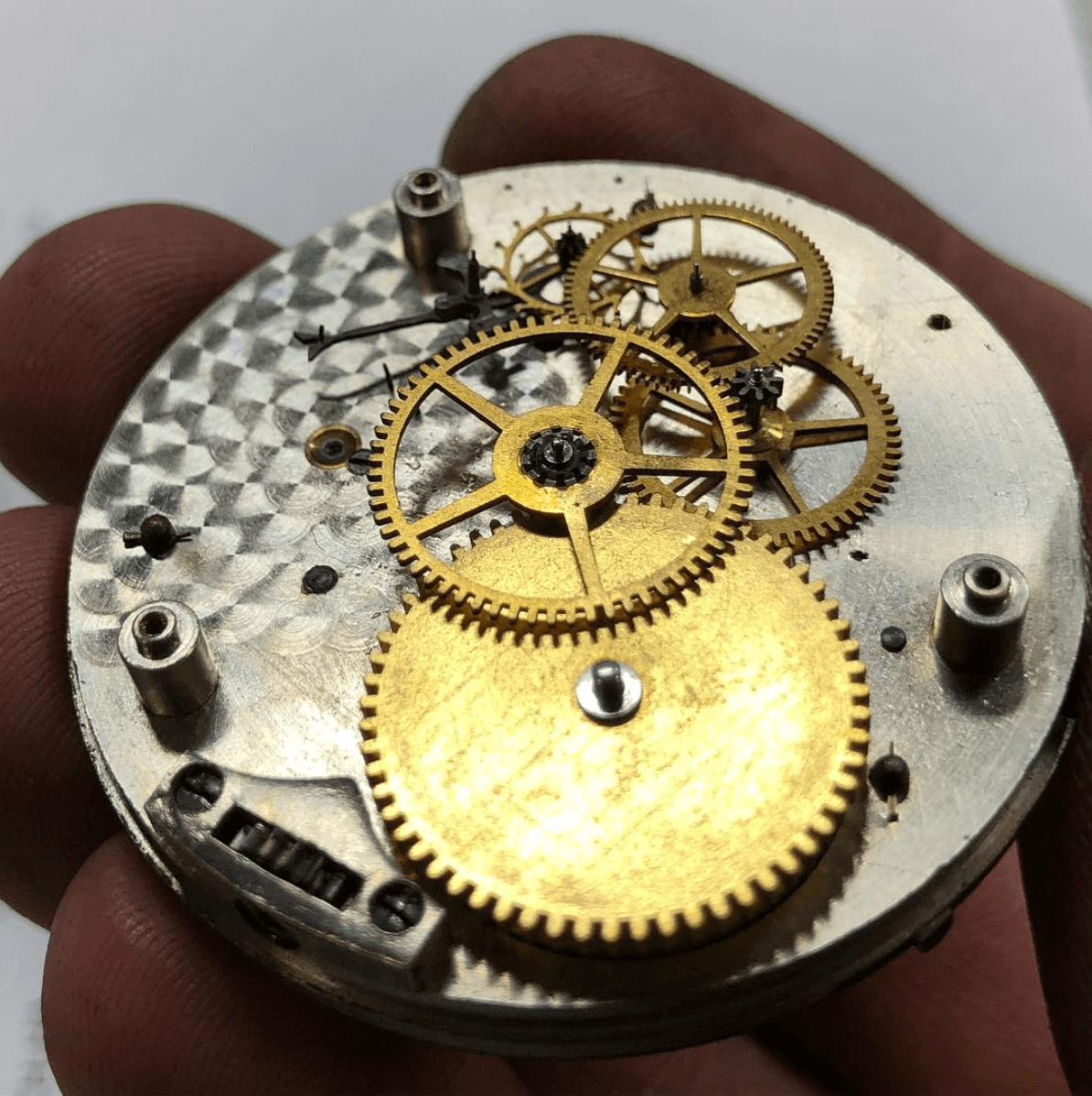

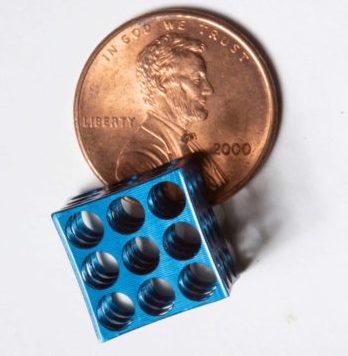

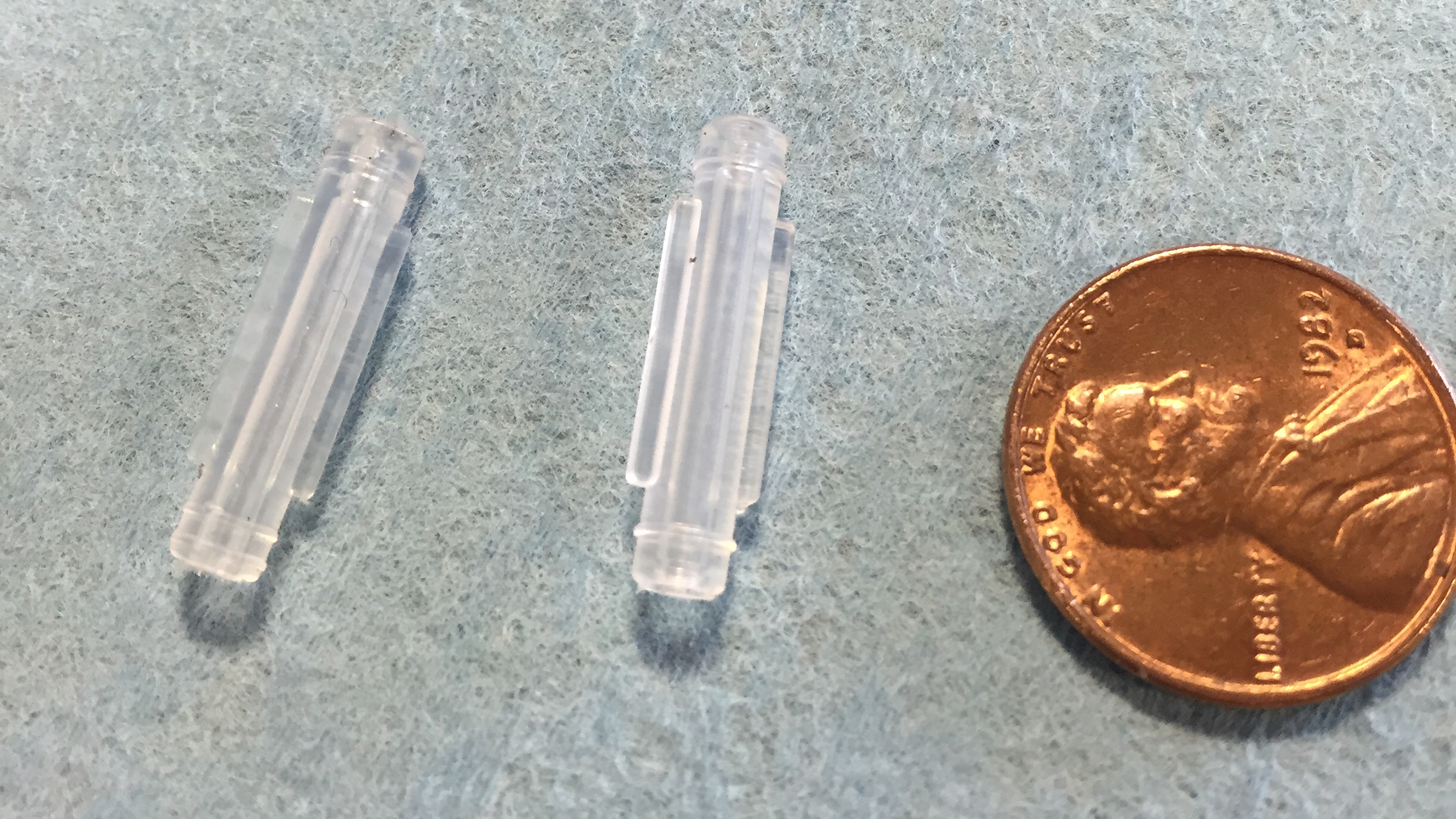

Complexities of Small Part Precision Machining

Looking for a precision machining partner who specializes in tiny parts? You might be wondering, how small is small? Here at KAD, we’re experts at machining

-

The Benefits of Custom Laser Engraving

Did you know that KAD provides custom laser engraving services? With our OmTech 30W Fiber Laser Marker, we can perform these services in-house: Marking: uses low-heat beams

-

How Our Precision Machine Shop Does More with Less

The ongoing manufacturing labor shortage was a recurring theme at this year’s International Manufacturing Technology Show (IMTS). In conference sessions and informal conversations, manufacturers from around

-

KAD Offers Citric Acid Passivation for Small Parts

New service alert! (Yes, another one!) Last month we announced that we now offer in-house powder coating services. Today, we’re excited to tell you about another

-

Modernizing Manufacturing Education: It’s Up to Us

Hello, reader—Brian Kippen here, owner and founder of KAD, back with another installment of our new series, The Future of Manufacturing. This series spotlights problems

-

New Service Alert: In-House Powder Coating at KAD

New service alert! The KAD team is excited to announce that we now offer in-house powder coating services. Many manufacturers outsource finishing treatments. While we've successfully worked

-

Teaching a New Generation of Manufacturers

Hello, reader—Brian Kippen here, owner and founder of KAD, back with another installment of our new series, The Future of Manufacturing. This series spotlights problems

-

Precision Machining: 5 Exotic Materials We Love Working With

Did you know KAD provides precision machining services for exotic materials? We love working with less common materials and are experts at machining anything from brass

-

How Do We Create More Diversity in Manufacturing?

Hello, reader—Brian Kippen here, owner and founder of KAD. Welcome to another installment of our new series, The Future of Manufacturing, wherein I share the

-

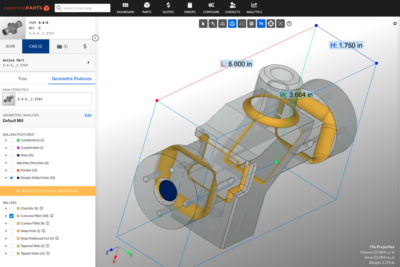

Our Software Enables Fast, Accurate Quoting for Precision Machining

At KAD, we believe that prototype machining should be as straightforward as possible. We look for opportunities to make the manufacturing process easier and more enjoyable

-

Rethinking the Manufacturing Workforce: Why KAD Trains “From Scratch”

Hello, reader—Brian Kippen here, owner and founder of KAD, back with another installment of our new series, The Future of Manufacturing. This series spotlights problems

-

Can Custom Tooling Save Time and Money? YES!

Did you know that custom tooling has the potential to save you time and money? Most people associate custom tooling with increased costs and lead times,

-

How to Adjust Your Part’s Design to Maximize Your Budget

Time and money are the two most significant considerations in both prototype machining and production manufacturing, and here at KAD, we're committed to helping our

-

What Type of Precision Machining Inspection Do You Need?

Inspection is a crucial step in the precision machining process, and at KAD, we take it extremely seriously. We offer four different types of inspection to

-

Oh Baby! Making a Priceless Heirloom With Precision Machining

At KAD, our passion for engineering consistently transforms manufacturing into an art form. We consider ourselves more than machinists—we're makers who take immense pride in

-

Overcoming Common Objections to Manufacturing Careers

Hello, reader—Brian Kippen here, owner and founder of KAD. Last month I introduced our new series, The Future of Manufacturing, wherein I'll share the problems

-

How KAD Is Expanding Our Network of Material Suppliers

Author: Brian Kippen I know you might be thinking. . . not another article about the global supply chain crisis! But bear with me because while I

-

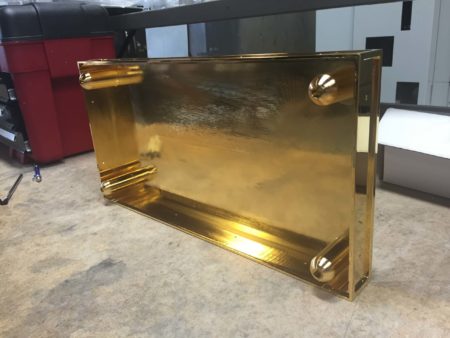

Red Metal Material Highlight: Brass Machining

Brass, a non-ferrous member of the red metal family, was inadvertently invented in 500 BCE when early civilizations melted copper with calamine, a zinc ore. However,

-

Introducing The Future of Manufacturing Series: Solutions for an Evolving Industry

Author: Brian Kippen Early in my career, I worked for a company with the unofficial motto: We don't do product problems; we do product solutions. That phrase

-

Liquid Silicone Rubber: A Faster Alternative to Injection Molded Silicone Parts

There's no doubt that injection molding is an excellent method for manufacturing silicone parts at scale. But the lead times and costs can be prohibitive

-

How 5-Axis Machining Saves You Time and Money

In 2021, we fortified our 5-axis CNC machining services and capabilities by adding a Matsuura MX-850 5-axis vertical machining center to our shop floor. This

-

Material Highlight: Magnesium Machining

What does early 20th-century photography have in common with modern precision aerospace parts? The answer is element number 12 on the periodic table—Magnesium (Mg). Named after

-

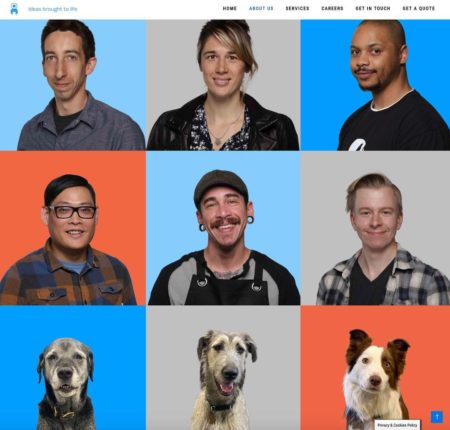

Education, Growth, and Autonomy: The Foundation of KAD’s Company Culture

What makes a precision machine shop a great place to work? People and projects are a big part of it, but company culture is also

-

Industry Spotlight: KAD is Your Go-To Automotive Machine Shop

Are you in search of a reliable automotive machine shop? We help build beautiful products for multiple industries here at KAD, but the automotive industry holds

-

4 Reasons to Choose KAD for Bridge Production

At KAD, we’ve built a reputation for being deeply committed to our craft. Our passion for engineering transforms prototyping into an art form. But we're

-

4 Prototype Model Design for Manufacturing (DFM) Tips

Prototyping is all about discovery. It’s an iterative process that allows you to finetune an idea until it's the best it can be. As bonafide prototype

-

Red Metal Material Highlight: Copper Machining

For over 10,000 years, humans have used copper for its many benefits, including thermal conductivity and corrosion resistance. Beyond its practical uses, copper possesses a

-

Why Choose KAD for Prototype Precision Machining Services?

Are you considering using one of the large distributed manufacturing platforms for prototype machining services? The perceived benefits of working with these companies are appealing at

-

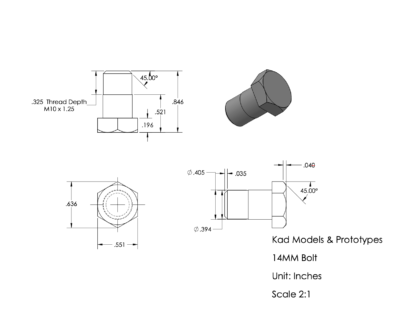

DFM Advice for CNC Turned Prototype Models

If you rely on CNC machining services for your prototype models, you’re already familiar with both CNC milling and CNC turning. These subtractive manufacturing methods are

-

Introducing KAD’s Pay It Forward Prototype Program

Prototyping is a demanding and expensive process. Once you have an idea, coming up with an initial design is simple enough, but transforming it into

-

Streamline Rapid Prototyping With the Right Documentation

Rapid prototyping designing and building multiple iterations of your prototype model—ideally over a short period of time. The changes in each iteration may be significant

-

Choosing the Right Silicone for Your Prototype Model

Silicone is a common manufacturing material, used in applications such as gaskets, surgical implants, and adhesives. It’s a highly durable, heat-resistant elastomer that performs reliably

-

When to Choose Additive vs. Subtractive Manufacturing for Your Prototype Model

Wondering when to use additive versus subtractive manufacturing for a prototype model? You may have a preference about designing for one manufacturing method over the other.

-

When to Choose Stock Components for Prototype Models

If you want to save time and money on your next prototype model, consider using stock components instead of having parts custom-made. It’s no secret that

-

Thin Wall Precision Machining for Prototype Models

Looking for a shop to machine a prototype model with thin walls? If so, you’ve probably received some pretty frustrating advice. Most shops advise clients to

-

Plastic Machining for Prototype Models

Could plastic be the right material for your next prototype model? There's a lot of talk about machining metals in manufacturing, but certain plastics can be

-

Choose the Right Stainless Steel or Alloy Steel for Your CNC Machined Prototype

Do you know which type of steel you need for your CNC machined prototype? Steel is a common manufacturing material that offers many benefits, including corrosion

-

Introducing Our Matsuura MX-850 5-Axis Vertical Machining Center

We’re thrilled to announce the addition of the Matsuura MX-850 5-axis vertical machining center to fortify our 5-axis CNC machining services and capabilities! Facilitating key manufacturing

-

Choose the Right Aluminum Alloy for Your CNC Machined Prototype

Aluminum is one of the most common material choices for CNC machining services. Known for being lightweight but strong and having excellent corrosion resistance, aluminum

-

How Manufacturers Can Mitigate Pandemic-Related Supply Chain Disruptions

The post-pandemic manufacturing world is markedly different from any period we’ve experienced before—and it’s mostly due to supply chains that can’t seem to catch a

-

When to Use Threaded Inserts in CNC Machined Prototypes

Does your prototype model really need threaded inserts? There are plenty of good reasons to incorporate threaded inserts like Heli-Coils into your prototype design. They’re great

-

Leveraging Automation for Short-Run Prototype Models

In manufacturing, there’s a common assumption that short-run prototypes are exorbitantly expensive because they require lengthy one-time setups. And while this assumption is certainly accurate

-

KAD’s Efficient Inspection Process for Prototype Models

When you partner with KAD for your machined prototype model, you can feel confident that it will meet the highest quality standards. We perform frequent

-

Why 2D Drawings Are Never Going Away for CNC Machined Assembly

When constructing a mechanical assembly, machine shops reference 3D models that show important features of the assembly’s components. But as advanced as they are, 3D

-

7 Questions to Ask When Choosing a CNC Machine Shop for Prototyping

Finding a machine shop is easy enough. But finding the right machine shop for your prototyping needs is much more challenging. A shop may offer all

-

Adjust the Internal Corner Radii of Fillets for Faster Machining and Lower Costs

Can the fillets in your prototype model be achieved with standard tooling? If not, you have a couple solutions: lengthen the tooling to achieve the desired

-

Low-Volume Production of Plastic Parts with Urethane Casting

When you need low-volume production quantities of plastic parts, you may think that your only options are having the parts machined or paying up for

-

Consider a Multi-Part Design with Mechanical Assembly For Your Prototype Model

Rome wasn’t built in a day, right? It all came together a bit at a time. Large, bulky parts are a lot like great cities. It’s

-

Reduce Lead Time On Your Prototype With the Right Post-Processing

When you need a prototype model completed quickly, it’s important to realize that any post-processing you require could increase your lead time. At KAD, we can

-

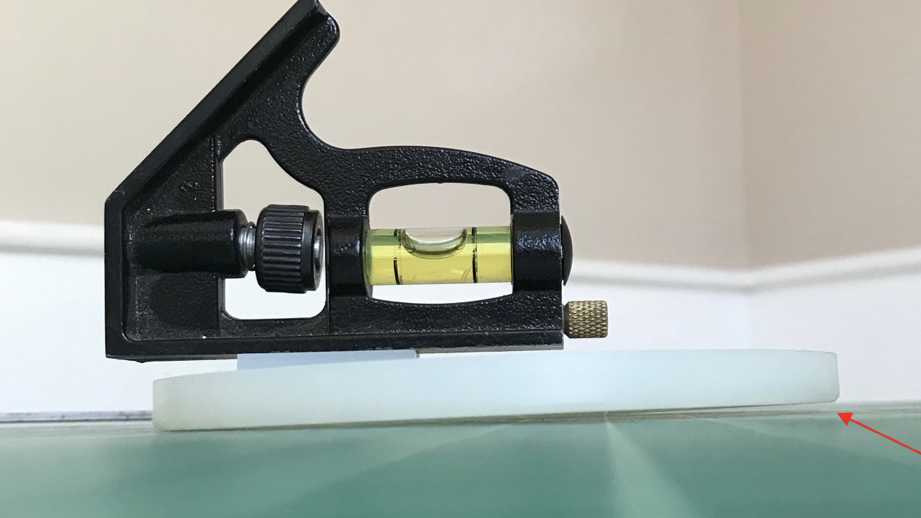

Why Calling Out Flat Surfaces On Your CNC Machined Part Matters

Are you working on a prototype model that’s flat on one or more sides? Whether you’re transitioning a prototype from an injection mold to CNC

-

Why Use Production Grade Silicone in Prototype Tooling?

The two most common ways to get silicone parts are by 3D printing or injection molding. Each has its own distinct advantage: 3D printing is

-

How KAD Streamlines Communication to Expedite Prototype and Production Manufacturing

Have you ever had a question about your manufacturing project and felt like you had no idea who to contact to get answers? Or even worse:

-

Consider Using Wood For Your Next CNC Machined Prototype

Since the days of early civilizations, craftsmen have worked with wood. Wood is pliable, durable, and easily accessible. It’s a timeless material, possessing a warmth

-

Optimize Undercuts to Prevent Complications During CNC Machining

Are undercutting complications costing you time and money? You may be able to design a sophisticated angled undercut in CAD, but that’s no guarantee that your