How Our Precision Machine Shop Does More with Less

The ongoing manufacturing labor shortage was a recurring theme at this year’s International Manufacturing Technology Show (IMTS).

In conference sessions and informal conversations, manufacturers from around the world celebrated the industry’s resilience in the face of a global pandemic while simultaneously acknowledging the pandemic’s negative impact on an already dwindling workforce.

KAD has experienced labor-related challenges firsthand in recent years. However, rather than letting these challenges get the best of us, we’ve dug deep to ask ourselves, “How can we stretch our resources without overworking our team members or falling short of our shop’s high standards for quality?”

Like many of the colleagues we heard from at IMTS, we’ve found that supplementing our team’s skilled labor with innovative automation technologies has been critical to keeping our shop up and running and enabling us to do more with less—another key theme at the conference.

Leveraging Automation to Optimize Our Workflows

Here are a few ways we’re using automation in our precision machine shop to optimize our workflows and do more with less internally:

Assigning repetitive tasks to robots

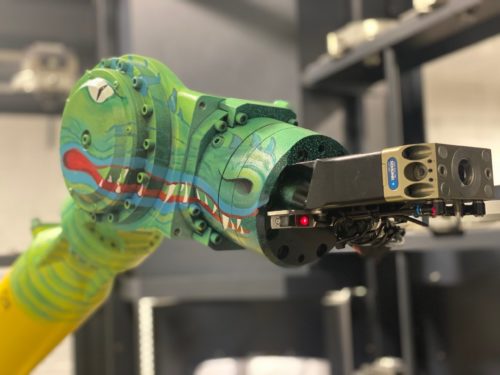

While our expert team members still perform all the precision machining tasks that require high levels of skill and experience, our two shop robots are ideally suited for tasks that are repetitive or place unnecessary strain on human workers.

After our team meticulously perfects and inspects the first part in a short-run production order, for example, we can program our Trinity AX5 robot to replicate it on our 5-axis mill. Our machinists are then freed up to move on to other high-level tasks rather than carrying out the monotonous work of pulling the material and running the program over and over.

Implementing lights-out machining

Since our robots don’t need sleep and work as well in the dark as under shop lights, we program them to perform certain operations after hours—i.e., lights out machining.

While most employees understandably prefer not to work third shift, burning the midnight oil doesn’t bother robots one bit. Programming them to work overnight keeps our team members from having to work undesirable hours and saves our precision machine shop a significant amount in electricity costs.

Supporting–not replacing–human workers

At KAD, we’d never replace a team member’s job with automation. Instead, we employ automation as a partner that helps us optimize our employees’ working conditions and empowers them to perform higher-level machining work.

By strategically using robots for certain tasks, we create better jobs for the employees we have while ensuring that we can meet our production demands. These improvements lead to higher employee retention, which helps us avoid the personnel costs associated with high turnover rates.

How We Help Clients Do More with Less

In addition to creating internal efficiencies to help our team and our business get more work done with fewer resources, we also find ways to help our clients do more with less money. Here are some solutions we have implemented:

Vertical integration

To supplement our precision machining services, we offer finishing services such as powder coating, laser engraving, passivation, and tumbling right here at KAD. Performing multiple services under one roof saves our clients valuable time and money by enabling them to work with just one stop instead of several.

Sophisticated quoting

Our automated quoting system helps clients save on material costs. When you request a material, it will suggest comparable alternatives that are more cost-effective so you can choose the best option for your budget.

Regional shipping

With bi-coastal shops in both California and Vermont, we’ll always machine your prototype model in the shop closest to you, saving on shipping costs and reducing our carbon footprint.

Budgetary troubleshooting

If we identify an opportunity to save you time or money, we’ll let you know. For instance, you may be able to transition to a more cost-effective material when you move from prototype to production. Or a finishing treatment you’ve chosen for production may not be entirely necessary during the prototype stage.

To learn more about how KAD can save you time and money while maintaining exceptional quality, request a quote today!