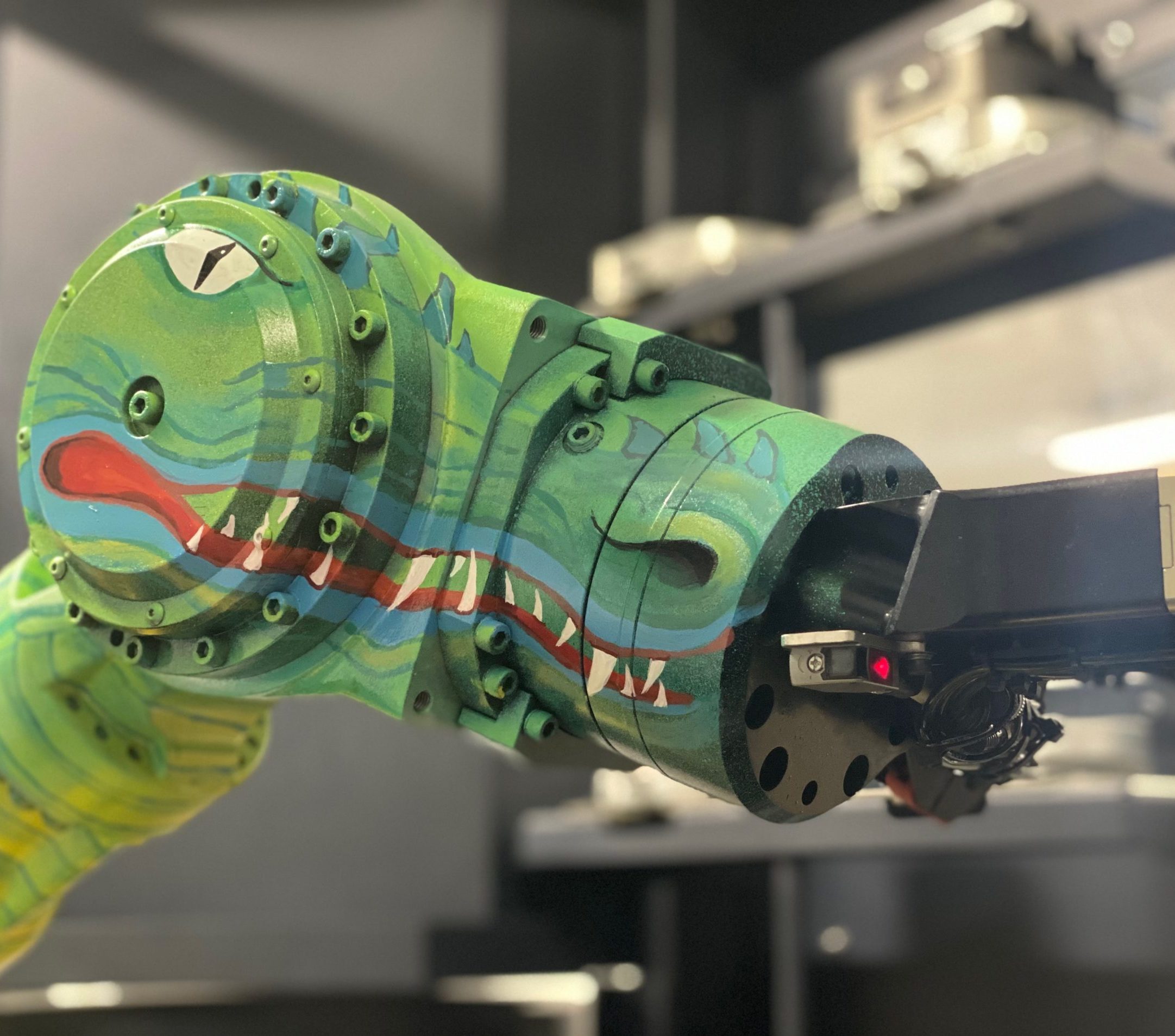

CNC Machining

We have extensive experience in machining complex parts where precision is critical, and support iterative processes for prototyping new products for your company.

We work with an array of materials including engineering plastics, aluminum and steel alloys, exotic metals such as Inconel, Tungsten and titanium, among others.

We have built a highly vetted network of quick response vendors for anodizing, plating, and paint or powder coats to support your products.

Silicone Molding

We determine a tooling strategy and design based on the data and project requirements you give us. Since we make our own tooling, your parts can be produced in a fraction of the time at a reasonable cost. We create production quality parts in quantities that range from less than 5 to several thousand.

We also provide support in materials selection for prototyping and production as needed. We have extensive experience with RTV, LIM, and HCR materials and provide support in determining material type. KAD also has a proven record of success with thin walls, precision insert Molding, and complex over-molding.

Urethane Casting

When multiples of a plastic part (or parts) are required and a machining operation is cost prohibitive, the urethane casting process can often solve the problem. We can duplicate our machined or your supplied pattern.

We have large selection of materials with a variety of physical characteristics are readily available; whether it’s rigid or elastomer, part or mold; we have suppliers and processes to fulfill most project requirements. Secondary operations are supported by a fully equipped conventional machine shop.

Materials We Work With

-

-

-

- Aluminum Alloys

- Copper

- Brass

- Nickel alloys

- Titanium

- Magnesium

-

-

-

-

-

- Steels

- Stainless Steels

- Copper Alloys

- Plastics

- Wood

-

-

HOW IT WORKS

In this field, expense and time matter the most. KAD utilizes its own high-end software to give instant machining feedback and pricing within hours after you send your product files. We will work with you personally to find a price that meets your budget. Operating our own factory certifies that every team member is proficient in the entire machining process. This allows KAD to physically inspect every manufacturing step to guarantee quality and commit to agreed deadlines.

Entire Assembly

Mechanical Assembly

*included but not limited to

- Complete System Assembly

- Tooling Assembly

- Hardware Integration

- STI, Fasteners & Dowel Pin

Finishing Services

*included but not limited to

- Media Blasting

- Painting and Powder Coating

- Anodizing

- Tumbling

Our Promise

KAD offers quick turn prototyping as well as production services. We work with you to get a clear picture of your needs and to ensure that final production will meet them in a timely way. KAD excels at the technique of machining and values the experience more than the finished product. By focusing on the journey of a prototype, our team inspects and perfects the manufacturing of the product from the beginning to its completion.

Testimonials

We are announcing

our new location!

As part of our continuous efforts to better serve our clients, we are excited to announce our new east coast location!