Inside Our First Pay It Forward Prototype Machining Project: The Making of a Guitar Mold

You can’t take your product idea to market without it. Investors need to see it before they’ll financially back you. But not every small business owner or philanthropist has the time and money it takes to build it. What is it? A prototype model. KAD’s Pay It Forward Prototype Program (PIFPP) helps innovators bring

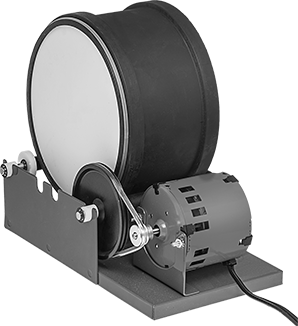

Is Tumbling the Right Finishing Process for Your Part?

At KAD, we’re proud to offer a wide range of finishing services, including sandblasting (also known as media blasting), small-part powder coating, hardware installation, and tumbling. We recently purchased two small tumblers—one for each of our West Coast and East Coast precision machine shops. Curious if tumbling is right for your prototype

The Power of Teamwork in Manufacturing

Hello, reader—Brian Kippen here, owner and founder of KAD, back with another installment of our new series, The Future of Manufacturing. This series spotlights problems we face in the manufacturing industry and what solutions KAD is testing. I hope this will be a collaborative process, and I would love to

Let’s Bring Manufacturing Education into the 21st Century

Hello, reader—Brian Kippen here, owner and founder of KAD. Welcome to another installment of our new series, The Future of Manufacturing, wherein I share the problems we face in the manufacturing industry and what solutions KAD is testing. My goal is to make this series a collaborative process, and I

Complexities of Small Part Precision Machining

Looking for a precision machining partner who specializes in tiny parts? You might be wondering, how small is small? Here at KAD, we’re experts at machining micro parts. We’ve tackled projects with parts smaller than a grain of rice—some even smaller than half of a grain! These contacts pictured above measure

The Benefits of Custom Laser Engraving

Did you know that KAD provides custom laser engraving services? With our OmTech 30W Fiber Laser Marker, we can perform these services in-house: Marking: uses low-heat beams to discolor a material’s surfaceEngraving: vaporizes a material’s surface to create precise groovesEtching: melts a material’s surface to create raised marks Indelible inking: adds paint to

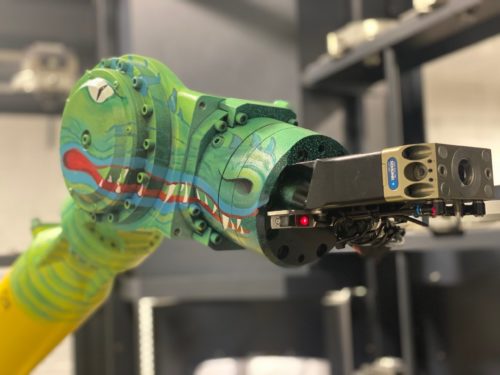

How Our Precision Machine Shop Does More with Less

The ongoing manufacturing labor shortage was a recurring theme at this year’s International Manufacturing Technology Show (IMTS). In conference sessions and informal conversations, manufacturers from around the world celebrated the industry’s resilience in the face of a global pandemic while simultaneously acknowledging the pandemic’s negative impact on an already dwindling workforce. KAD

KAD Offers Citric Acid Passivation for Small Parts

New service alert! (Yes, another one!) Last month we announced that we now offer in-house powder coating services. Today, we’re excited to tell you about another in-house finishing treatment we’re proud to provide our clients: citric acid passivation for small parts. What Is Passivation? Passivation is a popular post-processing chemical treatment that uses

Modernizing Manufacturing Education: It’s Up to Us

Hello, reader—Brian Kippen here, owner and founder of KAD, back with another installment of our new series, The Future of Manufacturing. This series spotlights problems we face in the manufacturing industry and what solutions KAD is testing. I hope this will be a collaborative process, and I would love to

New Service Alert: In-House Powder Coating at KAD

New service alert! The KAD team is excited to announce that we now offer in-house powder coating services. Many manufacturers outsource finishing treatments. While we've successfully worked with trusted powder coating suppliers for several years, bringing this capability into our precision machine shop will benefit our clients who need superior cosmetic finishes