Why 2D Drawings Are Never Going Away for CNC Machined Assembly

When constructing a mechanical assembly, machine shops reference 3D models that show important features of the assembly’s components. But as advanced as they are, 3D models aren’t always detailed enough to communicate the necessary information about the fit and function of each part.

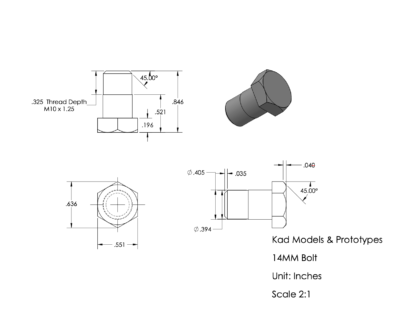

Whenever possible, it’s helpful to provide your CNC machine shop with a 2D drawing that details critical information like dimensions and tolerances. 2D drawing helps eliminate any unknowns, allowing a shop like KAD Models to make your assembly quickly, cost-effectively, and exactly to specification.

The Difference Between 3D Models and 2D Drawings

Including a 3D model and a 2D drawing in your quote may seem redundant at first. But the truth is that each one tells us different information:

- 3D models are considered the gold standard for production because they provide a three-dimensional scope of the project. With a 3D model, machinists can see all the features of a part or assembly. They can remove each individual component to show the contents and what the component interfaces with. Plus, 3D models are much faster to update than drawings.

- 2D drawings, on the other hand, provide critical to function (CTF) dimensions, which are the most valuable reference points for machinists. Although drawings are more labor-intensive to update, they contain all the requirements that are so important for a multi-part assembly.

It’s true that some software programs, such as SolidWorks, allow you to call out the critical dimensions of a part right in the 3D model. But machine shops don’t always have the compatible software necessary to read that information. Even if they do, the STEP files that most engineers send out may not contain this level of detail.

The Value of 2D Drawings

Here are a few examples of when a 2D drawing is especially valuable:

- Slip fit vs. press fit tolerances. 2D drawings clearly show the difference between slip fit tolerances (which require clearance between the mating parts) and press fit tolerances (which are almost impossible to separate). It’s an important differentiation that could change the function of a part. But 3D models typically show slip fit and press fit tolerances as having the same dimensions. 2D drawings, however, allow you to clearly call this information out.

- Walls and screw fasteners. Machinists need to know if screws should fit through two walls to fasten or just a single wall. 3D models can’t accurately show this information, but 2D models can.

- Line-to-line fit. 3D model technology allows product designers to fit two parts together even if it’s impossible to machine them that way. For example, a zero gap may work in your 3D model, but it won’t translate to the shop floor. Only 2D drawings clearly outline these specific details.

If a machinist doesn’t have a 2D drawing available, they may be left in the dark about the fit and function of the parts in an assembly.

Suppose a part has multiple same-size, standard tap drill holes. Although the customer knows what those holes will be used for, a machinist might not be able to discern this information from a 3D model.

Looking at the holes, the machinist could probably assume that they should tap and pour them—but what if these features are clearance holes for a 4-40 screw? Tapping and pouring the holes would completely affect the function of the part.

In most cases, machinists don’t want to make assumptions about the parts they’re working on. So when they run into a roadblock, they’ll pause machining to request additional information, which adds time to the project.

The bottom line is that when your mechanical assembly has critical requirements to ensure fit and function, giving your machine shop a 2D drawing helps you get your parts faster.

Do you need CNC machining services for your next assembly? Request a quote today from the experts at KAD!