Rethinking the Manufacturing Workforce: Why KAD Trains “From Scratch”

Hello, reader—Brian Kippen here, owner and founder of KAD, back with another installment of our new series, The Future of Manufacturing. This series spotlights problems we face in the manufacturing industry and what solutions KAD is testing. I hope this will be a collaborative process, and I would love to hear your thoughts on these topics. Drop me a line so we can connect and work to reinvigorate the manufacturing industry together.

In a world where manufacturers are constantly looking for our next hires, training is often overlooked. By training, I don’t mean onboarding and familiarizing new employees with the way your precision machine shop works. I’m talking about training people without much experience in manufacturing operations and services—”from scratch.”

Many manufacturing leaders avoid training because it’s time-consuming and expensive, but I believe it’s the best way to rebuild the workforce. In fact, it’s working well for us here at KAD.

What We Look For in Candidates

Taking a “training from scratch” approach means looking for candidates who possess three characteristics:

- Desire. We’re passionate about our work and seek teammates who walk through our door and want to be here just as much as we do.

- Soft skills. For someone to stretch and grow into a highly skilled worker, they must be able to learn, listen, process information, ask questions, and problem-solve.

- Technical expertise. There’s a reason this one is last on our list. Technical skills are important, but ultimately, they can be taught. If a candidate doesn’t have a strong work history but possesses the other characteristics, that’s okay with us.

It’s also worth mentioning that we’ll often prioritize relevant experience using modern technology over manufacturing experience.

The Problem with a Manufacturing Hierarchy

While this strategy works well for our team, I know it’s not the traditional approach. Historically, a hierarchical structure has denominated many manufacturing companies.

There’s an idea that new team members have to pay their dues and gain years of experience before being taught and trusted to do more nuanced work. Entry-level employees are told they’ll manage setups for several years before advancing to machinist roles.

It can take employees a long time to ascend to the job they want, leading to two negative outcomes for manufacturers:

- Delayed access to skilled machinists. The longer we keep new team members away from more complex work, the longer we wait for them to become competent enough to do it.

- High rates of turnover. Employees stuck in one station tend to get bored and leave when a better, more exciting opportunity arises.

As manufacturing leaders, we can’t have it both ways—we can’t seek new hires fresh from earning their two-year degree and demand that they have decades of experience.

If we are serious about enticing people to pursue careers in manufacturing, we must provide a clear, exciting, viable path for our employees. They must be able to see and experience the benefits of their work in order to remain committed to doing it.

KAD’s Approach to Training from Scratch

How do we ensure our employees gain comprehensive skills and can become assets to our business? We provide an immersive, team-led, cross-training environment.

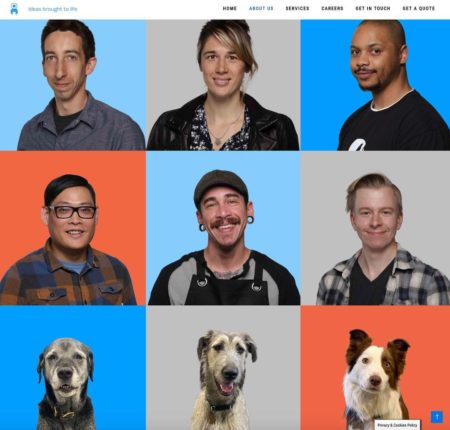

Our company culture is designed so that our whole staff shares the responsibility of training new team members within their first few weeks at work.

I pair the new hire with team members who need some help on a project or have downtime. I never pair a new employee with a teammate who is under a deadline or doesn’t have the capacity to teach thoughtfully.

We developed this system for two reasons:

1. To accommodate different learning styles

Everyone learns differently. Some people learn by doing, listening, or watching. Some need to be hands-on with a mentor. Some like to process information themselves before trying something new.

Cycling new hires through training with current employees exposes them to different teaching styles. Inevitably, the new team member will connect with someone who complements their learning style.

When we utilize our whole staff to help train, our new employees get a well-rounded and diverse education in real time, taking in many different perspectives.

2. To provide exposure to different areas of work

We expose new team members to all the different functions in our precision machine shop: programming operations, performing tool setups, and cutting materials using CNC lathes and mills. Recently, we hired a new employee who worked with three machines within their first four hours on the job!

Manufacturing is about creating. We make things. I don’t want my new hires doing setups for years before making a prototype model. A few months in, all of our new hires have machined half a dozen parts they programmed themselves.

Creating Manufacturing Careers vs. Jobs

A holistic approach to training new team members not only ensures that new hires generate revenue quickly but also helps employees stretch themselves. They grow from someone who took a manufacturing job into someone with a manufacturing career.

What’s the difference? A person with a career in manufacturing can leave one company, join a new one, and be productive immediately. Career employees require onboarding (assimilating with company culture and systems) but less training. They are directly contributing to the productivity of the business and generating revenue. In contrast, a person with a job in manufacturing must train for each new role they accept before they contribute to the company’s bottom line.

My goal is for our team to work at KAD as long as it fits them. But if and when they leave, I want them to have the skills to continue to thrive in their career.

There’s no question that hiring is a massive challenge in our industry. By adopting a “training from scratch” strategy, we’ve been able to seek out potential candidates with the interest and ability to learn and become stellar employees.

We don’t act as gatekeepers to the more nuanced work; we provide opportunities to learn and grow, which benefits our employees and also generates revenue faster for our company.

Finally, embracing a culture of cross-training and acknowledging different learning styles solidifies our collaborative, connected company culture. Yes—training takes time and costs money, but it’s a worthwhile investment.

What do you think? Does your company have a hiring strategy that’s working for you? I’d love to discuss how we can reinvigorate the manufacturing industry—drop me a line to connect.