How 5-Axis Machining Saves You Time and Money

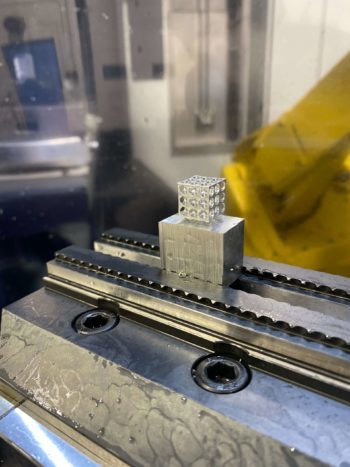

In 2021, we fortified our 5-axis CNC machining services and capabilities by adding a Matsuura MX-850 5-axis vertical machining center to our shop floor. This machine is an absolute powerhouse with the ability to achieve tight tolerances and manufacture large, bulky parts with exceptional speed.

A common misconception about 5-axis machining is that shops with these capabilities overcharge their customers for simple parts. While we can’t speak for all precision machine shops, at KAD, we’ve proven that 5-axis machining can reduce cost for our customers, even for low-volume production. And the benefits don’t stop there.

Here’s what you need to know about partnering with a 5-axis machine shop for your precision prototypes, parts, and components.

What Is 5-Axis Machining?

5-axis machining is a step up from standard 3- or 4-axis machining. There are two types of 5-axis machining: simultaneous and 3+2. Both 3+2 and simultaneous 5-axis machining move the cutting tool on the X, Y, and Z axes.

In the simultaneous 5-axis process, the machine also rotates the A, B, and C axes at the same time, maintaining constant contact between the tool and the part. Most modern 5-axis machines are capable of simultaneous machining, including ours.

In 3+2 5-axis machining, the fourth and fifth rotary axes (selected from the A, B, and C axes) position the part in a fixed orientation. With the 3+2 capability, we can orient the part multiple times in a single setup to accommodate various machining directions.

4 Benefits of 5-Axis Machining

Here are the four biggest benefits of 5-axis machining:

Minimal setups

Some of the fees associated with manufacturing parts relate to the programming and setup time. The industry standard is 20 minutes of setup time per face. That means if a component has three extra faces, you’ll need to pay for the hour a machinist takes to set them all up. With 5-axis machining, you’re only charged for the initial programming time since the technology reduces the number of setups required.

Reduced risk

Decreasing the number of setups also means lowering the risk of human error. Even with a highly skilled workforce, whenever you introduce the human element to a project, there’s a risk of accidents or mistakes that can directly impact cost and lead time. Processes like 5-axis machining that minimize human interaction are less risky.

Better accuracy and precision

It’s easier to maintain accuracy at tight tolerances with 5-axis machining because all faces of the part are manufactured simultaneously. Our MX-850 holds tolerances up to .0026mm/.0001″, which is even more precise than the average 5-axis CNC machine.

Easier inspection

5-axis machining reduces the time needed for inspection. Because parts are machined in one operation, we inspect them at completion instead of conducting inspections between each individual operation.

These benefits help customers save time and money on their manufacturing projects. 5-axis machining can even be cost-effective for single components, depending on the number of faces and setups required.

5-Axis Machining at KAD

Whether or not a part is a good candidate for 5-axis machining depends on various factors.

Generally, parts with complex geometries or undercuts that can’t be approached in a vertical environment are a great fit for this manufacturing method.

Part size is also an essential consideration. Large parts won’t fit unless a shop has an enormous 5-axis machine, and parts the size of thimbles are too small for most 5-axis machines.

Some customers assume 5-axis machining will be expensive because it’s a specialized manufacturing method. It’s true that shops often charge more for these services. But not us.

At KAD, we quote 5-axis machining at the same rate as 3-axis machining. Everyone on our team can program 5-axis machines, and we don’t withhold the capability based on project scope. Our priority is to use the technology that helps us make your precision parts as quickly as possible.

Our team can help you determine if 5-axis machining is the right manufacturing method for your project. Request a quote to get started.