Low-Volume Production of Plastic Parts with Urethane Casting

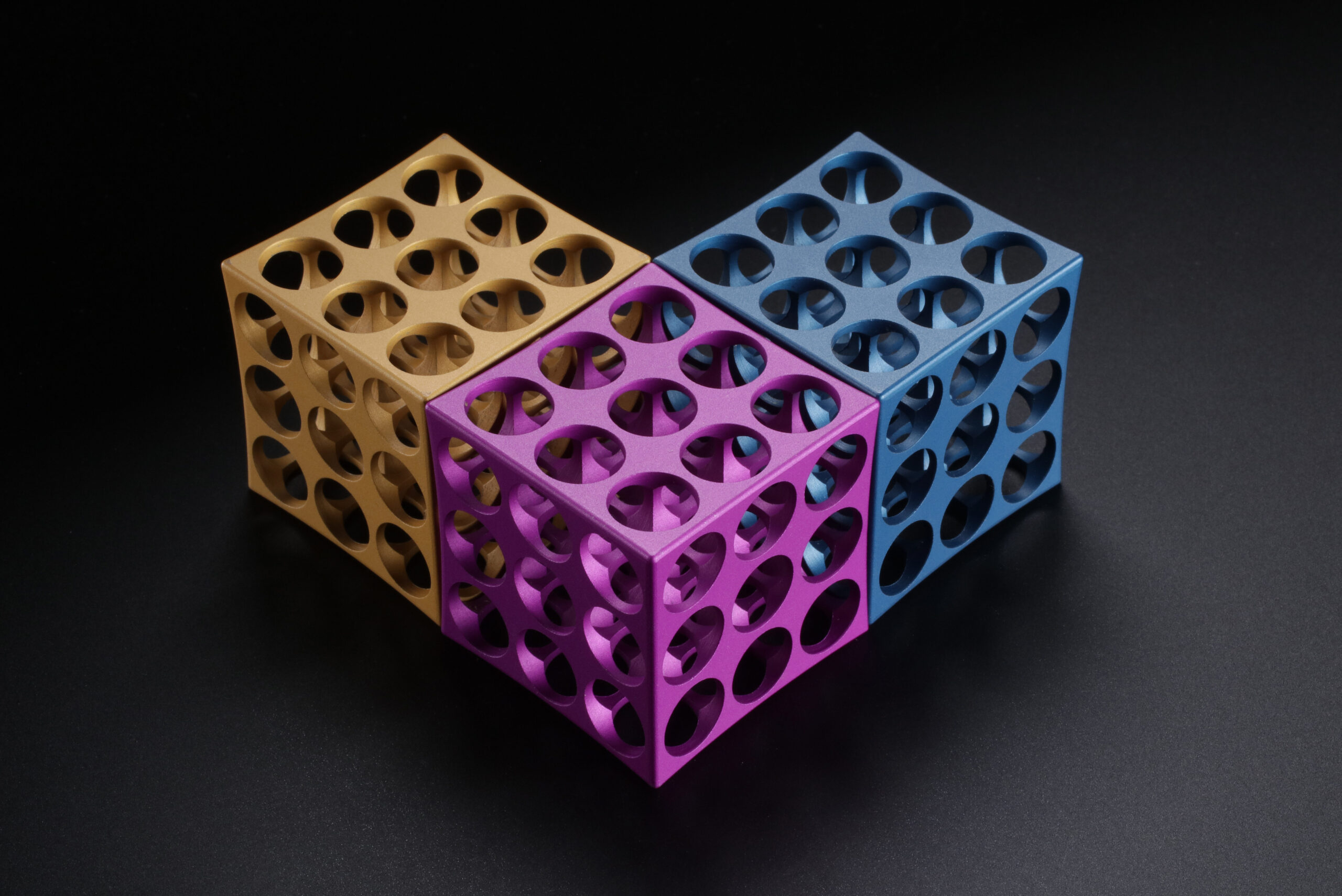

When you need low-volume production quantities of plastic parts, you may think that your only options are having the parts machined or paying up for injection molding. But there’s a third option that can be much more cost-effective: urethane casting. Urethane casting offers the same high quality and consistency of CNC

Consider a Multi-Part Design with Mechanical Assembly For Your Prototype Model

Rome wasn’t built in a day, right? It all came together a bit at a time. Large, bulky parts are a lot like great cities. It’s often best to design them in multiple components instead of trying to machine just one complex part. Designing an entire prototype model as one part may

Reduce Lead Time On Your Prototype With the Right Post-Processing

When you need a prototype model completed quickly, it’s important to realize that any post-processing you require could increase your lead time. At KAD, we can machine prototypes in 3-5 days. We can even complete in-house post-processing operations and stay within that time frame. But for certain finishing services that we

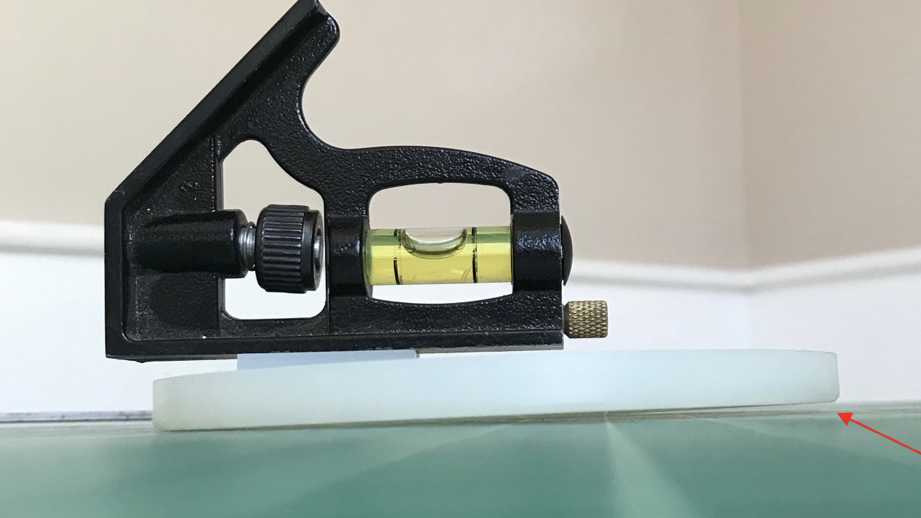

Why Calling Out Flat Surfaces On Your CNC Machined Part Matters

Are you working on a prototype model that’s flat on one or more sides? Whether you’re transitioning a prototype from an injection mold to CNC machining or creating a proof of concept for fit and function, if your model has a flat surface, there are a few things you should

Why Use Production Grade Silicone in Prototype Tooling?

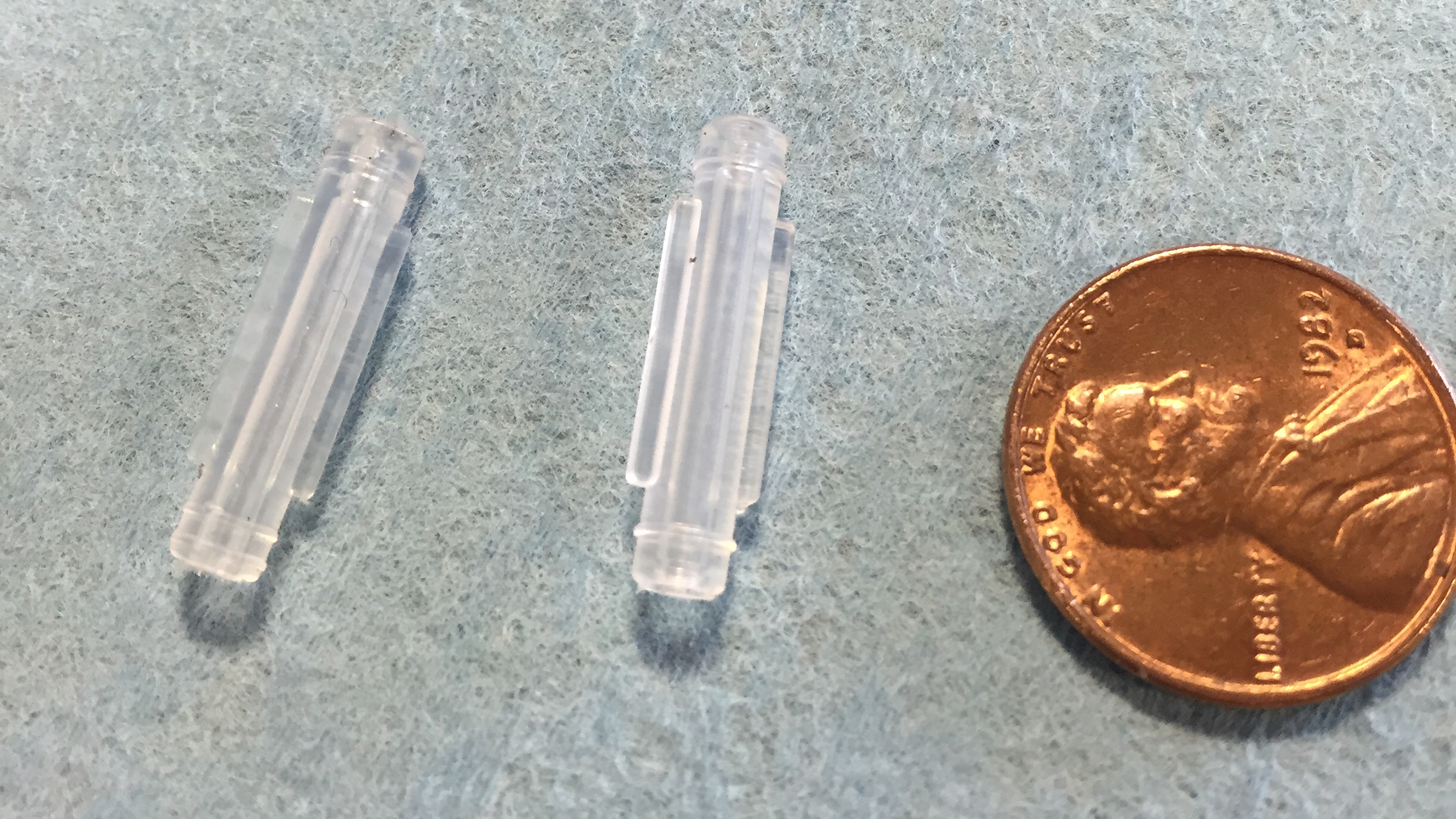

The two most common ways to get silicone parts are by 3D printing or injection molding. Each has its own distinct advantage: 3D printing is fast, and injection molding is highly accurate. But both methods have major pitfalls, too. If you’re building a silicone prototype using 3D printing, your prototype may

How KAD Streamlines Communication to Expedite Prototype and Production Manufacturing

Have you ever had a question about your manufacturing project and felt like you had no idea who to contact to get answers? Or even worse: have you ever been left in the dark when something went wrong with your part order, only to discover the issue once your timeline was

Consider Using Wood For Your Next CNC Machined Prototype

Since the days of early civilizations, craftsmen have worked with wood. Wood is pliable, durable, and easily accessible. It’s a timeless material, possessing a warmth and organic beauty that’s nearly impossible to replicate. In modern times, utilitarian wood objects are both practical and aesthetically pleasing. The Industrial Revolution ushered in a

Optimize Undercuts to Prevent Complications During CNC Machining

Are undercutting complications costing you time and money? You may be able to design a sophisticated angled undercut in CAD, but that’s no guarantee that your part will be machinable. Parts with small internal corner radii require undercutting with comparably small tools that take creativity to maneuver, potentially making the process