Choose the Right Stainless Steel or Alloy Steel for Your CNC Machined Prototype

Do you know which type of steel you need for your CNC machined prototype? Steel is a common manufacturing material that offers many benefits, including corrosion resistance, strength, and ductility. But as with other materials like aluminum, there’s no one-size-fits-all steel solution. Material properties, cost, and other factors vary from one type

Introducing Our Matsuura MX-850 5-Axis Vertical Machining Center

We’re thrilled to announce the addition of the Matsuura MX-850 5-axis vertical machining center to fortify our 5-axis CNC machining services and capabilities! Facilitating key manufacturing solutions for over 85 years, the Japanese manufacturing company Matsuura is an extremely well-regarded and established OEM that produces many highly regarded machines. And the

Choose the Right Aluminum Alloy for Your CNC Machined Prototype

Aluminum is one of the most common material choices for CNC machining services. Known for being lightweight but strong and having excellent corrosion resistance, aluminum is also a favorite of machinists. The material is easily machinable and yields consistent, high-quality prototype models. But not all aluminum alloys are created equal. For

How Manufacturers Can Mitigate Pandemic-Related Supply Chain Disruptions

The post-pandemic manufacturing world is markedly different from any period we’ve experienced before—and it’s mostly due to supply chains that can’t seem to catch a break. From a lack of available materials at the top to lags in transportation at the bottom, buyers are left to deal with unconventionally long lead

When to Use Threaded Inserts in CNC Machined Prototypes

Does your prototype model really need threaded inserts? There are plenty of good reasons to incorporate threaded inserts like Heli-Coils into your prototype design. They’re great for reinforcing screw threads and transferring forces on soft materials. But for many applications, standard drilling and tapping can be a more functional and cost-effective solution

Leveraging Automation for Short-Run Prototype Models

In manufacturing, there’s a common assumption that short-run prototypes are exorbitantly expensive because they require lengthy one-time setups. And while this assumption is certainly accurate for many machine shops, it’s simply not the case here at KAD. We’re committed to expediting prototype and production manufacturing for our clients. For short-run prototype

KAD’s Efficient Inspection Process for Prototype Models

When you partner with KAD for your machined prototype model, you can feel confident that it will meet the highest quality standards. We perform frequent in-process inspections to ensure you receive a functional, well-designed part that meets all critical requirements. Performing in-process inspections for a prototype model helps us make quality

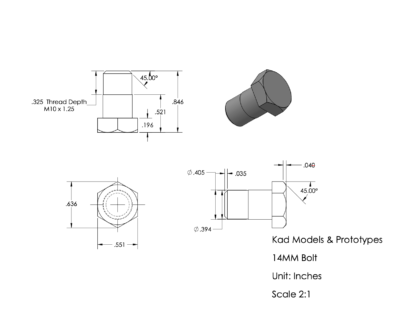

Why 2D Drawings Are Never Going Away for CNC Machined Assembly

When constructing a mechanical assembly, machine shops reference 3D models that show important features of the assembly’s components. But as advanced as they are, 3D models aren’t always detailed enough to communicate the necessary information about the fit and function of each part. Whenever possible, it’s helpful to provide your CNC

7 Questions to Ask When Choosing a CNC Machine Shop for Prototyping

Finding a machine shop is easy enough. But finding the right machine shop for your prototyping needs is much more challenging. A shop may offer all the capabilities you’re looking for, but that doesn’t mean you can trust them with your parts. Capabilities alone aren’t enough. The fact is that who

Adjust the Internal Corner Radii of Fillets for Faster Machining and Lower Costs

Can the fillets in your prototype model be achieved with standard tooling? If not, you have a couple solutions: lengthen the tooling to achieve the desired angle or adjust the angle in the design for standard tooling. The simple choice is just to change the tooling, right? Not necessarily. Going from standard