Red Metal Material Highlight: Copper Machining

For over 10,000 years, humans have used copper for its many benefits, including thermal conductivity and corrosion resistance. Beyond its practical uses, copper possesses a distinctive beauty. As it ages, oxidation causes the material to develop a vibrant teal coating known as a patina. But in the context of modern manufacturing,

Why Choose KAD for Prototype Precision Machining Services?

Are you considering using one of the large distributed manufacturing platforms for prototype machining services? The perceived benefits of working with these companies are appealing at first glance. Distributed manufacturing platforms promise to consolidate the manufacturing supply chain—a tempting proposition given the volatile state of global supply chains. Customers only need

DFM Advice for CNC Turned Prototype Models

If you rely on CNC machining services for your prototype models, you’re already familiar with both CNC milling and CNC turning. These subtractive manufacturing methods are used to machine materials like aluminum, steel, and many thermoplastics. But the two processes are quite different, and they work best for different types of

Introducing KAD’s Pay It Forward Prototype Program

Prototyping is a demanding and expensive process. Once you have an idea, coming up with an initial design is simple enough, but transforming it into a prototype model takes a significant investment of time and money. And yet, that physical proof of concept is essential in securing the financial backing

Streamline Rapid Prototyping With the Right Documentation

Rapid prototyping designing and building multiple iterations of your prototype model—ideally over a short period of time. The changes in each iteration may be significant or small, but it’s critical that each file is properly named and organized to ensure the customer and their manufacturing partner are on the same

Choosing the Right Silicone for Your Prototype Model

Silicone is a common manufacturing material, used in applications such as gaskets, surgical implants, and adhesives. It’s a highly durable, heat-resistant elastomer that performs reliably under harsh environmental conditions. But not all silicones are alike. Factors like temperature and chemical resistance, mechanical properties, and durability vary from one silicone to the

When to Choose Additive vs. Subtractive Manufacturing for Your Prototype Model

Wondering when to use additive versus subtractive manufacturing for a prototype model? You may have a preference about designing for one manufacturing method over the other. Perhaps your material choice or part geometry is only really suited for one of these applications. But having a bigger-picture understanding of both of these

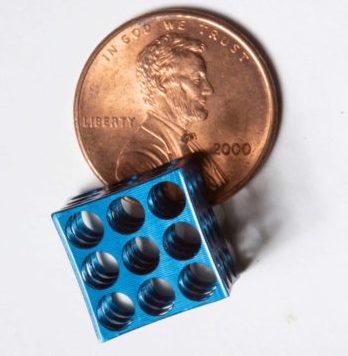

When to Choose Stock Components for Prototype Models

If you want to save time and money on your next prototype model, consider using stock components instead of having parts custom-made. It’s no secret that we specialize in complex projects here at KAD. We jump at the opportunity to solve complicated prototype CNC machining problems, and we love bringing intricate

Thin Wall Precision Machining for Prototype Models

Looking for a shop to machine a prototype model with thin walls? If so, you’ve probably received some pretty frustrating advice. Most shops advise clients to design their thin walls within a 10:1 height to thickness ratio. But there’s a problem with this recommendation: by our calculations, walls with a 10:1

Plastic Machining for Prototype Models

Could plastic be the right material for your next prototype model? There's a lot of talk about machining metals in manufacturing, but certain plastics can be excellent choices for prototype to low volume production needs. Some clients use plastic to prove out a concept prior to injection molding, while others leverage plastic