How KAD Is Expanding Our Network of Material Suppliers

Author: Brian Kippen I know you might be thinking. . . not another article about the global supply chain crisis! But bear with me because while I am here to talk about supply chain disruptions and material shortages negatively impacting the manufacturing industry, I'm interested in discussing solutions. Actual, feasible solutions. My team

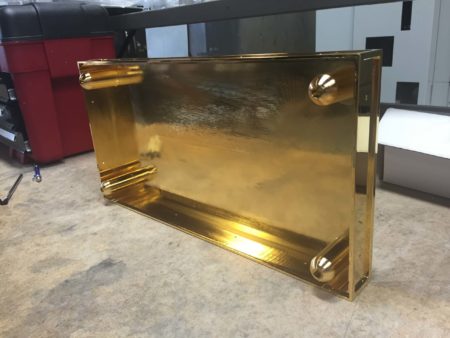

Red Metal Material Highlight: Brass Machining

Brass, a non-ferrous member of the red metal family, was inadvertently invented in 500 BCE when early civilizations melted copper with calamine, a zinc ore. However, brass wasn’t commonly used until the Industrial Age because zinc wasn’t a naturally occurring resource in many parts of the world. In the 18th century,

Introducing The Future of Manufacturing Series: Solutions for an Evolving Industry

Author: Brian Kippen Early in my career, I worked for a company with the unofficial motto: We don't do product problems; we do product solutions. That phrase struck a chord with me. I think of KAD as a precision machine shop in the business of providing solutions. When customers submit an RFQ for

Liquid Silicone Rubber: A Faster Alternative to Injection Molded Silicone Parts

There's no doubt that injection molding is an excellent method for manufacturing silicone parts at scale. But the lead times and costs can be prohibitive if you’re only in the prototyping phase. In most cases, spending upwards of $30K on steel tooling for a prototype model or bridge production project

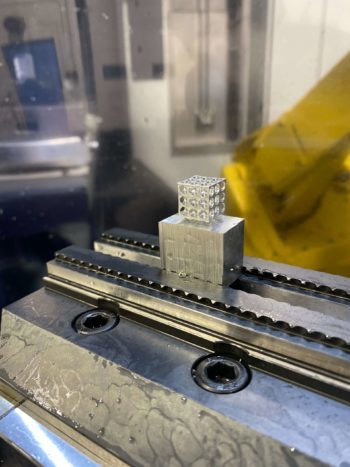

How 5-Axis Machining Saves You Time and Money

In 2021, we fortified our 5-axis CNC machining services and capabilities by adding a Matsuura MX-850 5-axis vertical machining center to our shop floor. This machine is an absolute powerhouse with the ability to achieve tight tolerances and manufacture large, bulky parts with exceptional speed. A common misconception about 5-axis machining

Material Highlight: Magnesium Machining

What does early 20th-century photography have in common with modern precision aerospace parts? The answer is element number 12 on the periodic table—Magnesium (Mg). Named after the Greek region Magnesia, magnesium is an abundant element found in seawater and the earth’s crust. This cost-effective metal boasts exceptional machinability and a high strength-to-weight

Education, Growth, and Autonomy: The Foundation of KAD’s Company Culture

What makes a precision machine shop a great place to work? People and projects are a big part of it, but company culture is also essential. Historically speaking, the manufacturing industry hasn't exactly prioritized workers' social-emotional needs. Words like "company culture" don’t always appear in the precision machine shop playbook. In

Industry Spotlight: KAD is Your Go-To Automotive Machine Shop

Are you in search of a reliable automotive machine shop? We help build beautiful products for multiple industries here at KAD, but the automotive industry holds a special place in our hearts. Before launching our precision machine shop in 2011, Founder Brian Kippen worked as an auto mechanic in Vermont. Over

4 Reasons to Choose KAD for Bridge Production

At KAD, we’ve built a reputation for being deeply committed to our craft. Our passion for engineering transforms prototyping into an art form. But we're more than a prototype shop—we're also a precision machine shop equipped to handle bridge production. What Is Bridge Production? Bridge production—also known as bridge manufacturing—bridges the gap

4 Prototype Model Design for Manufacturing (DFM) Tips

Prototyping is all about discovery. It’s an iterative process that allows you to finetune an idea until it's the best it can be. As bonafide prototype machinists, we transform many prototype drawings into tangible products, and we can often recognize design flaws before machining ever begins. If you want to bypass some