How to Adjust Your Part’s Design to Maximize Your Budget

Time and money are the two most significant considerations in both prototype machining and production manufacturing, and here at KAD, we’re committed to helping our clients save both.

Sometimes, when clients receive a quote from us, they’ll ask what can be done to further reduce costs. We are contract manufacturers by trade but solution finders at our core—we’ll always work with you to identify ways to maximize your budget.

3 Questions that Can Save Money During Manufacturing

If you’re looking to save money on your project, start by asking yourself these three questions about your part’s design:

1. Does my part require finishing treatments at this stage?

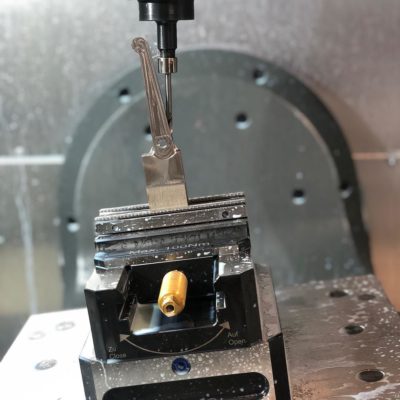

Prototype machining is our bread and butter. Our clients often need components for a prototype made quickly and cost-effectively so that they can assess usability.

In these cases, finishing treatments that may be applied to end-use parts may be unnecessary. If your primary goal at this stage of your project is to ensure your prototype model functions as intended, you can typically forgo costly finishing treatments; save them for the production run.

If a specific finish is critical to the success of your prototype model, we can work with you to determine if there are more cost-effective alternatives.

2. Are my part’s features and dimensions designed for optimal manufacturability?

It’s our job to help clients bridge the gap between design and manufacturing. When clients want to reduce costs, we advise them to avoid unnecessary features and dimensions that pose considerable manufacturability challenges.

For instance, including an extraneous fillet might seem inconsequential from a design perspective, but the tighter the fillet, the longer the cycle time on the shop floor.

Ironically, some of the simplest part designs can be exceptionally difficult to machine. A client sent us an RFQ for parts shaped like horseshoes but with square corners. A squared-off horseshoe may be easy enough to draw, but manufacturing those parts would be a whole different story.

3. Does my part need to be machined on every face or have other cosmetic considerations?

Aesthetics matter at a shop specializing in prototype machining. As a KAD best practice, we machine every face of a part to help achieve optimal surface flatness and ensure a uniform cosmetic appearance.

We want every part we make to look its best, but that extra effort on our end might not be necessary for your project. If you’re looking to quickly get a preliminary proof of concept and aren’t concerned with cosmetics at this stage of your project, consider noting “mill finish acceptable” on your RFQ. If you can accept the stock material however it comes, you’ll cut costs considerably.

When weighing cosmetic considerations, remember to think about the material you’re using.

For example, if you want your acrylic parts to be completely transparent, and you tolerance the thickness of the part, expect a few extra operations to get the final product you’re looking for. Machining the surfaces and then polishing them until they’re clear again will add up in time and money.

If you are primarily seeking to understand how well the mechanical properties of acrylic perform in your prototype, transparency may not matter, and you can forgo those additional costs. Keep in mind that if your part requires optical clarity, both the mechanical properties and the aesthetic appearance are important.

One Thing You Can Do to Maximize Your Project Budget

So, what happens when you’ve asked yourself these questions, have answers, and still would like to reduce the cost of your project?

The most crucial step of all: connect with your manufacturing partner!

To truly maximize your budget, tell your manufacturing partner what you’re trying to achieve when you request a quote. Proactively provide information that answers questions such as:

- What’s the intent of the part?

- Where are you in the process of development?

- Are you doing a quick test for fit, form, and function?

- Do you need a final-seeming, aesthetically pleasing part?

- Have you been through many design revisions?

- Are you midway through and trying to estimate production costs?

- Are you open to design changes?

Don’t be afraid to ask questions of your own when you submit your RFQ. Your precision machining partner cares about your success and has access to critical knowledge and information that could make or break your project. When in doubt—ask.

At KAD, we always look forward to working with our clients on their next project, and the more our clients share up front, the better equipped we are to quickly make the parts they need.

Are you ready to start your next prototype model or production order? Request a quote today—and tell us all about your project!