Reduce Lead Time On Your Prototype With the Right Post-Processing

When you need a prototype model completed quickly, it’s important to realize that any post-processing you require could increase your lead time.

At KAD, we can machine prototypes in 3-5 days. We can even complete in-house post-processing operations and stay within that time frame. But for certain finishing services that we outsource to trusted vendors, we can’t always guarantee such a short lead time.

If you want to keep costs low and lead times short, we’ll help you determine the right finishing for your prototype—if it even needs post-processing in the first place.

Does Your Prototype or Model Need Post-Processing?

Before you decide on post-processing, take a moment to consider the purpose your prototype will serve.

Does your prototype really need to be finished right now to fulfill its purpose?

If the answer is no and you want it machined and delivered quickly, consider taking your model as-is with no post-processing. These guidelines can help you determine what your model needs based on the function it’ll serve:

- If you need verification of mechanical fixturing, you’ll want a complete, finished part with all required attributes to ensure the correct form, fit, and function.

- If you have a full evaluation prototype that requires testing and evaluation to confirm that the product will work as intended, get it fully finished.

- If you want to test corrosion resistance, strength, or properties dependent on the type of finishing, get your part fully finished.

- If your part is a proof of concept or assembly, you may not need post-processing if the finishing isn’t a determining factor.

- If you’re working with a cosmetic prototype, consider getting one part finished to verify it’s exactly what you want, then have the others completed later.

Choosing the Right Post-Processing Method for a Short Lead Time

If you need post-processing, take control of your lead time by understanding your finishing options and how long each one will take. We recommend following these guidelines to keep your lead time manageable.

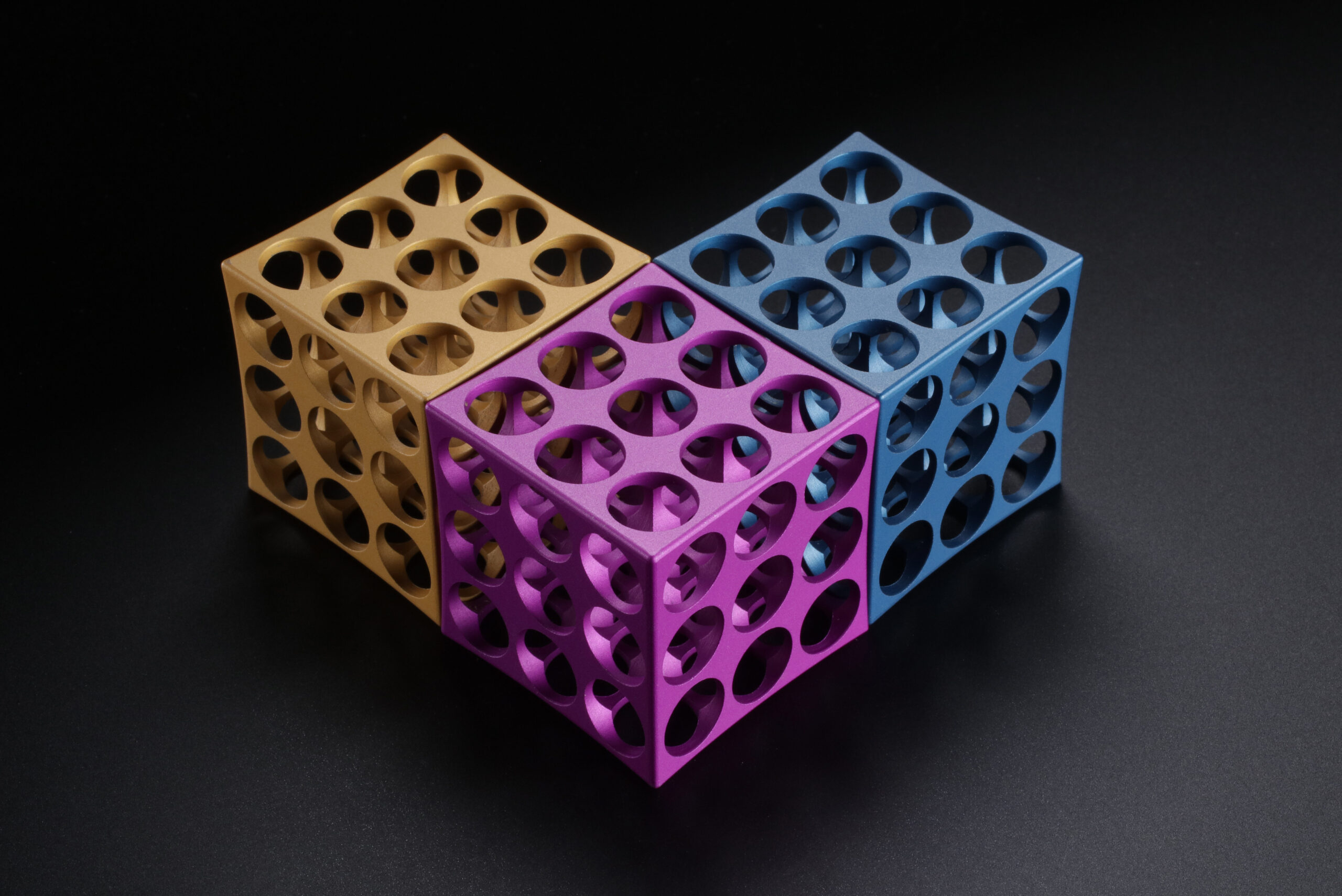

Choose from our in-house finishes. At KAD, we’re proud to offer these in-house finishes to our clients to help keep lead times as short as possible:

- Media blasting

- Tumbling

- Small-part powder coating

- Hardware installation

We can perform each of these operations quickly so that lead time is virtually unaffected. But if you need a service like plating, anodizing, or helicoiling, we’ll send your prototype to a local trusted vendor.

Outsourcing always increases lead time, which is why we suggest choosing from one of our in-house finishing options when possible.

Know how much time each process takes. Post-processing times vary greatly depending on the finish. If possible, choose the method that best aligns with the timing of your project:

Tumbling and media blasting are the fastest finishes, with powder coating close behind. Powder coating only takes 20 minutes to complete, but adds hours as we wait for it to set.

Custom paint, plating, and other finishing operations are longer processes that can add days to your lead time.

Determine the complexity of your part. Simple parts take less time to finish, whereas complex parts take more time.

If, for example, you have a large part with threaded holes that need to be masked prior to plating, the process of masking those holes will increase lead time. Any other specific requirements will also add complexity and time to your project.

Need Post-Processing for your Prototype? Be Specific!

When you determine what type of post-processing you need for your prototype, communicate those needs with your machine shop early on. And be specific!

For example, stating that you need your model hard anodized isn’t detailed enough because using the wrong anodize can actually alter your tolerances.

The tolerance changes caused by Type II anodizing are indiscernible, but Type III anodizing can alter tolerances by half a thousandth to as much as three thousandths an inch per surface! If you don’t call out your plating specifications, the chosen finish will be whatever hardcoat the plater is using at the time, which could be detrimental to your prototype model.

To avoid this problem, detail and specify plating requirements using ASTM (American Society for Testing and Materials) callouts so you get exactly what you want.

Still need help determining the right post-processing method for your prototype? Speak with a professional at KAD today and we’ll be happy to assist you!