Liquid Silicone Rubber: A Faster Alternative to Injection Molded Silicone Parts

There's no doubt that injection molding is an excellent method for manufacturing silicone parts at scale. But the lead times and costs can be prohibitive if you’re only in the prototyping phase. In most cases, spending upwards of $30K on steel tooling for a prototype model or bridge production project

Choosing the Right Silicone for Your Prototype Model

Silicone is a common manufacturing material, used in applications such as gaskets, surgical implants, and adhesives. It’s a highly durable, heat-resistant elastomer that performs reliably under harsh environmental conditions. But not all silicones are alike. Factors like temperature and chemical resistance, mechanical properties, and durability vary from one silicone to the

Why Use Production Grade Silicone in Prototype Tooling?

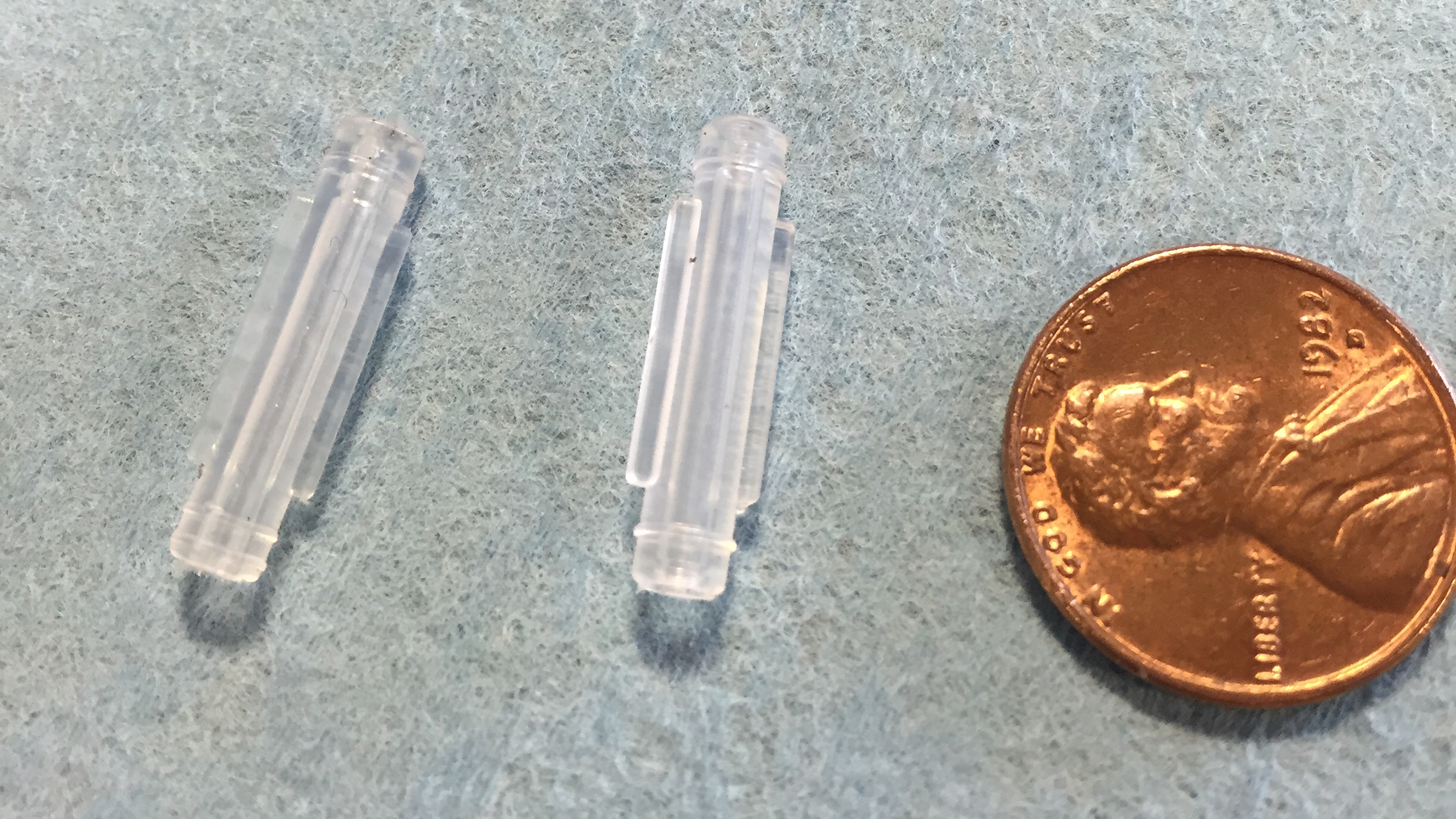

The two most common ways to get silicone parts are by 3D printing or injection molding. Each has its own distinct advantage: 3D printing is fast, and injection molding is highly accurate. But both methods have major pitfalls, too. If you’re building a silicone prototype using 3D printing, your prototype may