Reduce Lead Time On Your Prototype With the Right Post-Processing

When you need a prototype model completed quickly, it’s important to realize that any post-processing you require could increase your lead time. At KAD, we can machine prototypes in 3-5 days. We can even complete in-house post-processing operations and stay within that time frame. But for certain finishing services that we

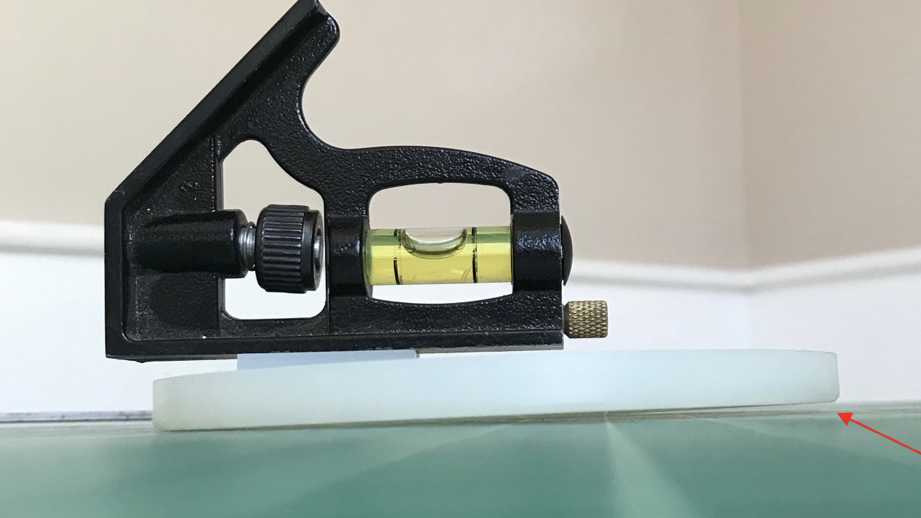

Why Calling Out Flat Surfaces On Your CNC Machined Part Matters

Are you working on a prototype model that’s flat on one or more sides? Whether you’re transitioning a prototype from an injection mold to CNC machining or creating a proof of concept for fit and function, if your model has a flat surface, there are a few things you should

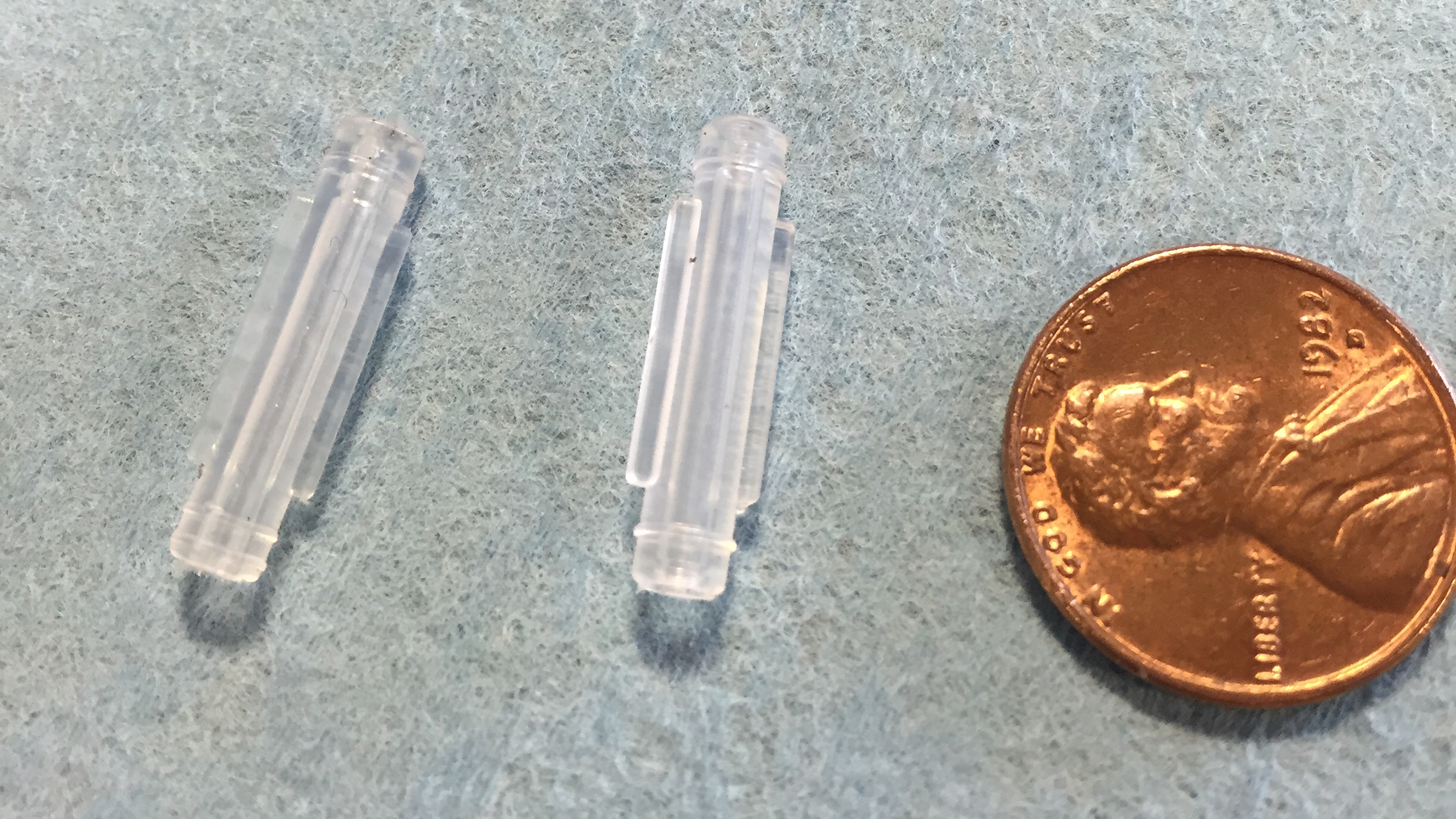

Why Use Production Grade Silicone in Prototype Tooling?

The two most common ways to get silicone parts are by 3D printing or injection molding. Each has its own distinct advantage: 3D printing is fast, and injection molding is highly accurate. But both methods have major pitfalls, too. If you’re building a silicone prototype using 3D printing, your prototype may