what we do

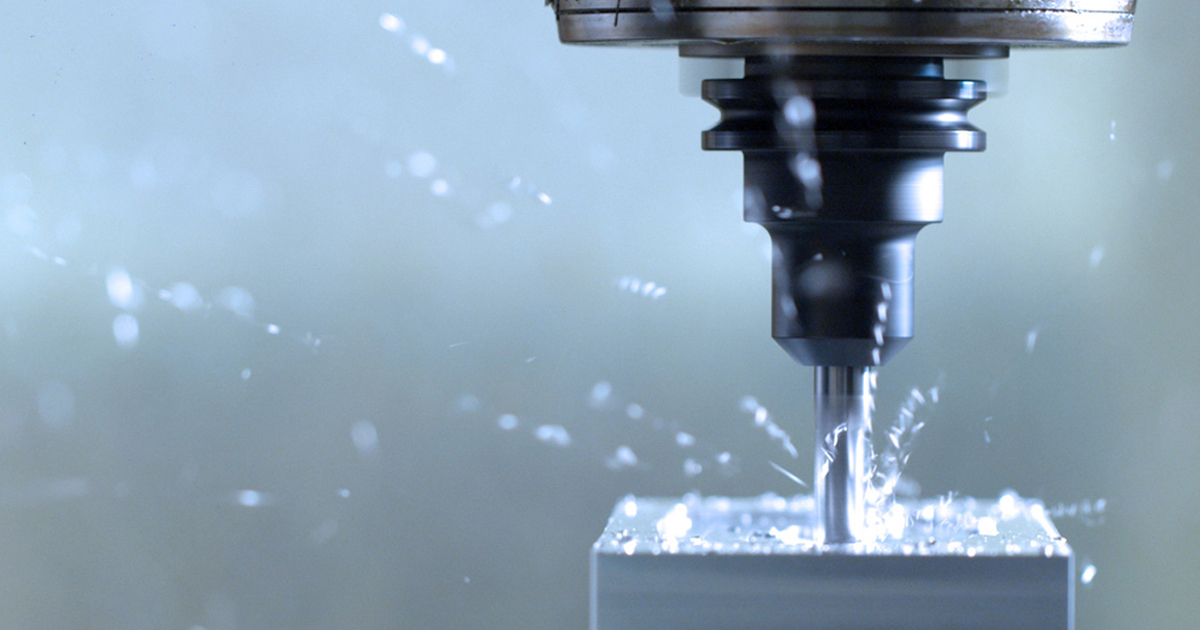

a new way to create

KAD’s passion for engineering transforms prototyping to an artform. As artists, we take pride in our creations from start to finish. We manufacture your product directly from the model and manually inspect every order – ensuring consistently high quality for every part we make.

OUR CAPACITY

CNC MACHINING

SILICONE MOLDING

URETHANE CASTING

a new way to create projectS

KAD team specializes in CNC Machining, Silicone Molding and Urethane Casting. We are capable of making any size prototype using many different raw materials. Programing a piece at a time, KAD has manufactured a 128 inch long part using a CNC machine.

OUR BELIEFS

communication

KAD believes that making prototypes should not be an arduous process. The shop makes it easy on clients with its light atmosphere, experienced team and transparent communication. Creating hardware today is time consuming and expensive but it doesn’t have to be impossible.

Support

KAD believes everybody should be able to receive the prototype needed to complete their goal. The expert process with our software system quickens the manufacturing operation and we are open to discuss price to fit any budget. The KAD team values supporting clients from the very beginning of the product’s development to the very end.

Brian Kippen

Christopher Bastain

Thinh Quoc Dang

Peter Derkacz

Alex Woods

Brandan Palmer

Atlas

Moose

clients

SAY HI!

create project

Partnering with KAD you get a team of highly skilled machinists collaborating on your project. We provide an edge for creative ability, pace and product excellence. Building a prototype is a process, let’s get started on your prototype journey together.

want to join us?

KAD is happy and open to add more esteemed machinists to continue to increase the team’s dexterity. Check out the Career’s page to see what it means to be a part of the company and what we look for in a colleague. Do not hesitate to send in your resume!

We would love To work with you. Join the team.

We are always looking for motivated, creative and skilled individuals to add to our team. Visit our careers page to view available job positions.